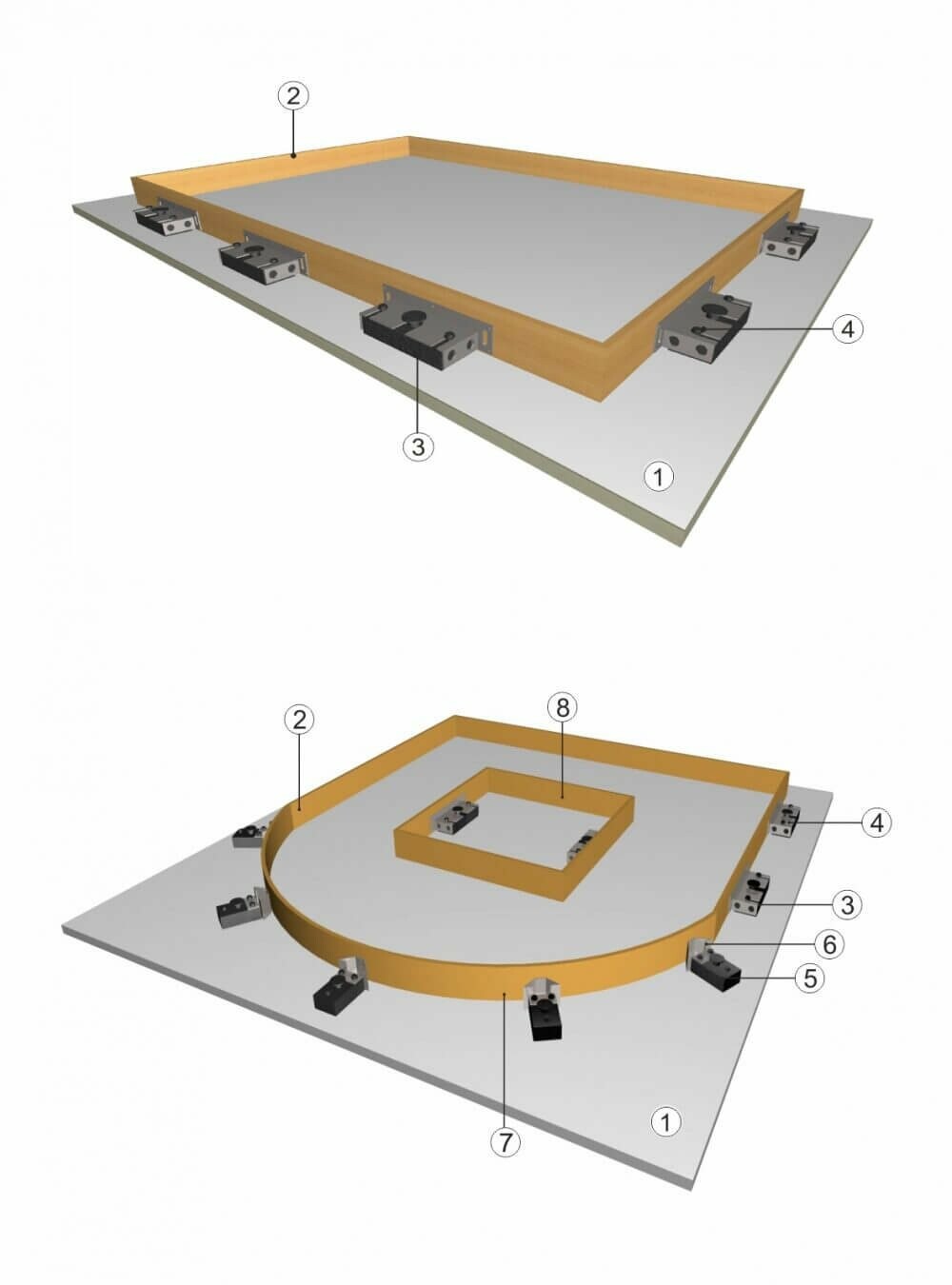

Magnetic formwork in production is an innovative technology that is already finding its application today. It is used for the rapid and efficient creation of reinforced concrete structures. Magnetic formwork is a structure used to shape concrete products in the plant. Traditional formwork is made of metal or wood, which can take a lot of time and require a lot of labor and resources. Magnetic formwork, on the other hand, is a more modern and efficient method. It consists of magnetic blocks containing magnets, which are then connected together by magnets to form the shape into which concrete is poured. Once the concrete has hardened, the formwork can be easily separated.

Magnetic formwork in production has several advantages over traditional formwork. It is much faster and easier to use, which reduces production time and labor costs. In addition, magnetic formwork provides higher precision and quality of the structure, as all formwork elements are in strict accordance with plans and drawings. Another advantage of magnetic formwork is its environmental efficiency. Additionally, magnetic formwork can be reused multiple times, further reducing waste.

Magnetic formwork is becoming increasingly popular in concrete product factories around the world

The advantages of magnetic formwork in production make it a versatile solution that can be used in all situations. For example, it may be suitable for creating curved or complex shapes. It is compatible with all types of concrete and can work in special conditions such as high humidity or low temperatures. Its use reduces production costs and minimizes the impact on the environment. In addition, it improves the accuracy and quality of the structure, which enhances safety and durability.

If you are planning to manufacture any concrete prefabricated object, the use of magnetic formwork may be a good choice. However, before making a decision to use this technology, a careful analysis is necessary to ensure that it is suitable for your project and complies with all safety requirements and standards.

Overall, magnetic formwork is an innovative technology that provides many advantages over traditional formwork. It reduces production time and costs, improves the accuracy and quality of the structure, and promotes environmental efficiency. Currently, it is widely used in many precast concrete productions and is becoming increasingly popular day by day.