The production of reinforced concrete products is an important branch of the construction industry. Reinforced concrete products are used in construction to create reliable and durable structures such as bridges, buildings, roads and many others. However, successful production of reinforced concrete products is impossible without the right choice of equipment. In this article, we will look at the key aspects of selecting equipment for the production of reinforced concrete.

Determining your needs:

Before you start selecting equipment, it is necessary to determine the needs of your enterprise. What kind of products are you going to produce? What volume of production are you planning? The answers to these questions will help you decide on the type of equipment you need and its capacity.

Consultation with experts:

Choosing equipment for the production of reinforced concrete is a complex task, and it is important to get advice from experienced professionals. Talk to an engineer or consultant who specializes in reinforced concrete production. They can help you decide which equipment will be most suitable for your needs.

Types of equipment:

There are many types of equipment needed for the production of reinforced concrete. Here are some of the main types:

- Molds and formwork: These are used to create molds and formwork for casting concrete products. The molds can be metal, wood or plastic, depending on the specific needs of the production.

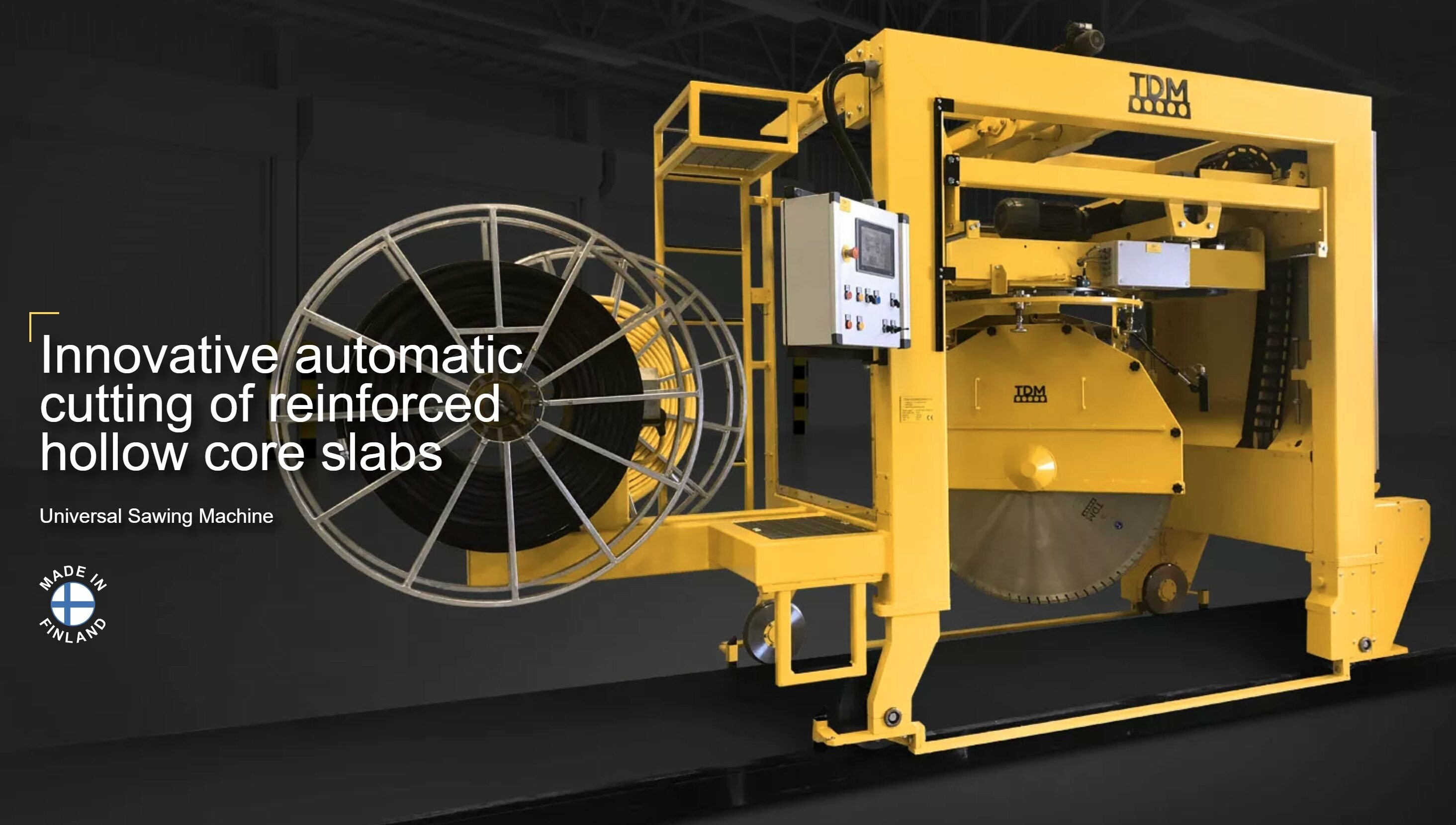

- Hollow core slabs extruder: For producing different hollow core slabs which are usable in the building.

- Concrete mixing plant: Mixing plant are used to produce the concrete mix. Choose the right mixer for your production volume and mix quality requirements.

- Vibropress: Vibropresses are used to compact concrete and remove air from it, this machines make concrete paving slabs. They also help give products the desired shape and texture.

- Automated control systems: Modern technologies allow automation of the production process of reinforced concrete, which increases its efficiency and quality.

Quality and reliability

When choosing equipment, always look at its quality and reliability. Investing in high quality equipment can justify itself in the future, as it will serve for many years without serious breakdowns.

Staff training

In addition to purchasing equipment, you should also provide training for your staff. Operators need to know how to properly operate the equipment and follow safety precautions.

The choice of equipment for the production of reinforced concrete products is an important stage in the creation of a successful enterprise. The right equipment will help you achieve high quality products and increase production efficiency. Do not forget to consult with experts and pay attention to quality and reliability when selecting equipment. As a result, your reinforced concrete products will be in demand in the building materials market.