Modern construction places high demands on the quality, durability, and cost-effectiveness of structures. In this context, prestressed and post-tensioned concrete technology is becoming a key tool for developers seeking reliability and cost optimization. The use of prestressed reinforcement allows for the creation of stronger and more durable reinforced concrete elements with lower resource costs.

The essence of the method: tensioning and pouring

The essence of the technology lies in the pre-tensioning of reinforcement using mechanical, electrothermal, or combined methods, followed by the pouring of concrete mix. After it hardens, the tensioned reinforcement transfers the compressive force of the structure. This eliminates tension zones, minimizes the risk of cracking, and allows for complex engineering tasks, including long spans and high loads.

Where it is used in practice

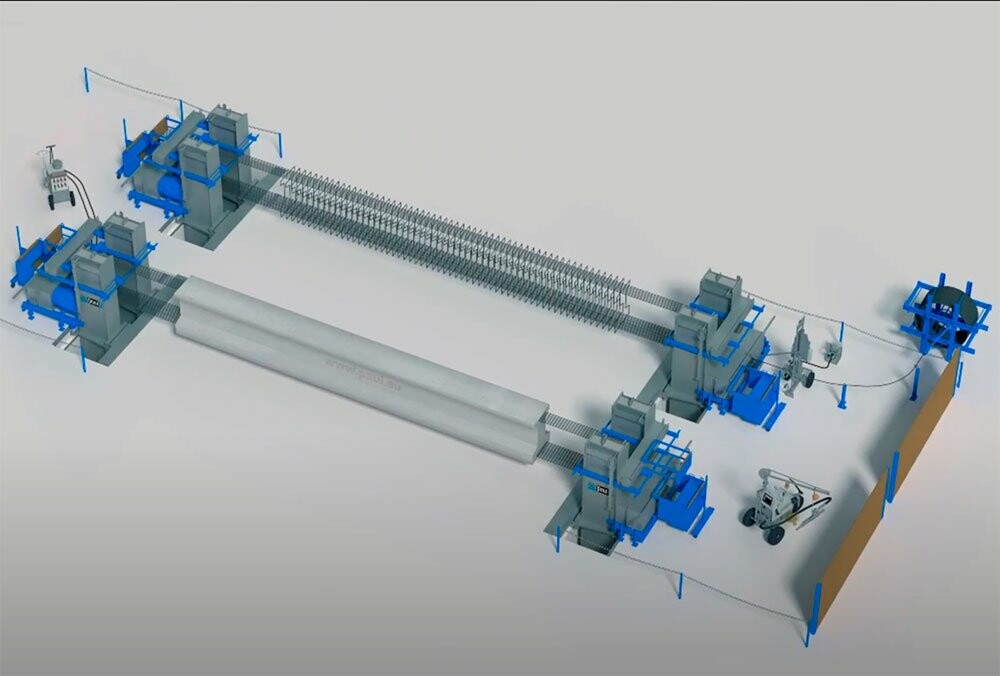

In practice, the technology is actively used in reinforced concrete plants for the production of floor slabs, beams, columns, and piles. It is also applicable on construction sites for the construction of bridges, industrial structures, and monolithic structures. Equipment from TDM Engineering, including hydraulic jacks, anchor grips, and mobile pumping stations, ensures the precise execution of all tensioning stages.

Advantages for the customer and contractor

Prestressed and post-tensioned concrete technology has a number of practical advantages:

- Reduction in structural weight by up to 40% without loss of strength

- Reduction in reinforcement volume by up to 50%

- Increased span lengths without intermediate supports

- Resistance to seismic and dynamic loads

- Increased accuracy and speed of installation

- Possibility of implementing complex architectural solutions

All these advantages directly affect the cost of the project, delivery times, and operational characteristics.

Conclusion and proposal from TDM Engineering

In an environment of fierce competition and high responsibility for the quality of buildings, prestressed and post-tensioned concrete technology is becoming the optimal choice for ambitious projects. TDM Engineering offers integrated solutions — from design support to equipment supply and staff training. Our experience, proprietary technologies, and European quality will give you a sustainable advantage. Contact us today — we will help you implement your projects with maximum efficiency and minimum risk.